1. Common Misunderstandings and Risks in the Procurement Process

Demand Confirmation Bias

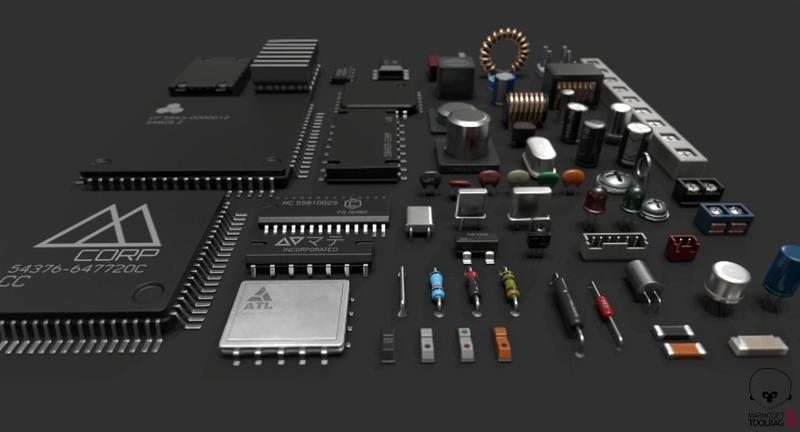

The models and parameters of passive electronic components (such as resistors, capacitors, and inductors) usually contain complex suffix codes, such as the material of the capacitor (C0G/X7R/Y5V), the accuracy of the resistor (1%/5%), and the packaging form (such as SOD-123 and 1206). HK EQGOO LIMITED should pay special attention when purchasing:

Model suffix trap: The same model may correspond to different packages or parameters. For example, the 1N4148WS diode has multiple packaging forms such as DO-35 and SOD-123. If it is not clearly marked, it may cause the production line to stop.

Technical standard omissions: High-frequency circuits need to select low-loss capacitors (such as C0G materials), and consumer electronic devices must comply with ESD protection standards (such as IEC61000-4-2). Improper selection may cause product performance problems.

Improper supplier selection

Excessive price reduction leads to quality risks: Some suppliers may provide non-original or refurbished components to reduce costs, such as mixing 5% precision resistors with 1% precision, resulting in reduced product stability.

Single supplier dependence: If there is excessive reliance on a supplier, when the supplier has production capacity problems or geopolitical risks (such as changes in Southeast Asian export policies), it may lead to supply chain disruptions.

Defective contract terms

Fuzzy quality standards: Failure to clearly reference industry standards (such as GB/T or RoHS) in the contract may lead to disputes during acceptance. For example, a company was eventually forced to bear the loss of customer returns because it did not stipulate lead-free solder requirements in the contract.

Unclear delivery period and breach of contract liability: If the contract does not stipulate compensation terms for overdue delivery, the supplier may delay delivery, affecting HK EQGOO LIMITED‘s production plan.

Logistics and inventory management risks

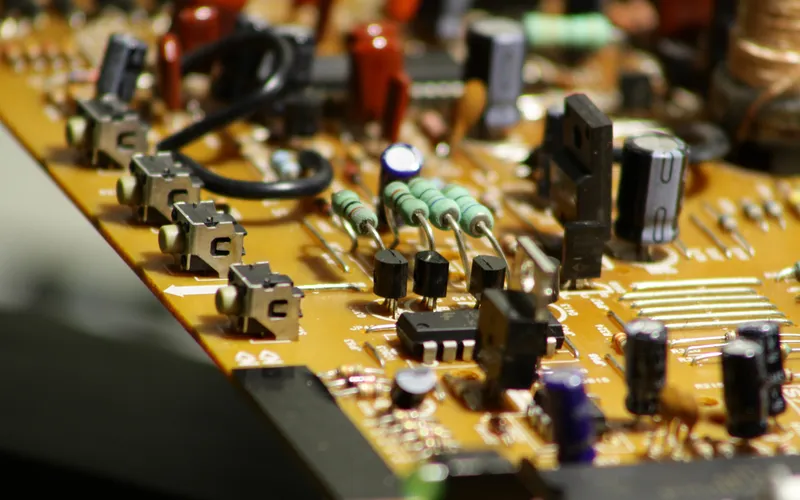

Transport damage: Passive components (such as ceramic capacitors) are susceptible to vibration damage during transportation. If shockproof packaging is not selected or freight insurance is not purchased, it may result in high losses.

Inventory backlog and shortage: Insufficient forecasting of market demand may lead to inventory backlog (such as general resistors) or shortage (such as AI chips), affecting capital turnover and production efficiency.

2. Procurement optimization strategies and suggestions

Precision demand management

Cross-department collaboration mechanism: Establish a joint review team composed of R&D, procurement, and quality departments to clarify technical parameters (such as withstand voltage and temperature coefficient) during the BOM list confirmation stage, and verify feasibility through sample testing.

Application of digital tools: Use electronic procurement systems (such as ERP) to automatically verify model suffixes and packages to avoid human errors. For example, set rules in the system to force the selection of package types when purchasing 1N4148WS.

Supplier life cycle management

Multi-dimensional evaluation system:

Technical capabilities: Investigate whether the supplier has automotive certification (such as IATF 16949) or high-frequency component design capabilities (such as RF inductors for 5G base stations).

Supply chain resilience: Give priority to suppliers with layouts in Southeast Asia (Vietnam, Malaysia) and South America (Mexico) to disperse geopolitical risks.

Credit rating: Collect supplier reputation through industry exhibitions and B2B platforms (such as Huaqiang Electronics Network), and refer to historical delivery on-time rates (required ≥95%).

Strategic cooperation and risk sharing: Sign long-term agreements with core suppliers, agree on price adjustment mechanisms (such as quarterly fluctuations based on silicon material prices), and require suppliers to provide capacity reservation commitments.

Refined design of contract terms

Quality terms: Clearly cite national standards (such as GB/T 2693-2021 “Fixed Capacitors”), and agree on the sampling inspection ratio (such as 5% sampling per batch) and the process for handling defective products (such as replacement within 7 days).

Logistics terms: Specify the mode of transportation (such as air transportation for high-value components), route (avoid politically turbulent areas) and insurance liability (covering the entire transportation process) in the contract.

Dispute resolution: Agree on arbitration terms (such as submitting to the Hong Kong International Arbitration Center) to reduce the risk of cross-border litigation.

Dynamic monitoring of supply chain risks

Intelligent inventory warning: Set a 3-6 month safety inventory for scarce components (such as AI chips), shorten it to 1-2 months for general components (such as resistors), and monitor inventory levels in real time through IoT technology.

Market trend tracking: Regularly analyze industry reports (such as the MLCC demand forecast for 2025) and adjust procurement strategies in advance. For example, lock in long-term agreements before AI chip prices rise.

Emergency plan formulation: Establish a list of secondary suppliers. When problems occur with the main supplier, switch to a backup supplier within 48 hours to ensure that the production line does not stop.

3. Technological innovation and sustainable development

Substitution strategy: Using Chinese components in the field of power semiconductors (such as IGBT of Yangjie Technology) and mid-range MLCC can reduce costs by 15%-30%, while reducing dependence on imported supply chains.

Green procurement practice: Give priority to environmentally friendly materials that meet RoHS standards (such as lead-free solder) to meet the energy efficiency requirements of the EU and North American markets and enhance the international competitiveness of products.

Digital transformation: Introduce blockchain technology to achieve supply chain traceability, ensure the transparency of the entire process from production to delivery of components, and enhance customer trust.

4. Conclusion

Passive electronic component procurement is the core link of HK EQGOO LIMITED‘s supply chain management. Through precise demand definition, supplier optimization, contract risk management and supply chain resilience construction, enterprises can effectively reduce procurement costs (target reduction of 10%-15%), improve delivery efficiency (shorten delivery cycle by 20%), and establish differentiated advantages in fierce market competition. It is recommended to conduct procurement performance evaluation every quarter and continuously optimize processes to ensure consistency with corporate strategic goals.