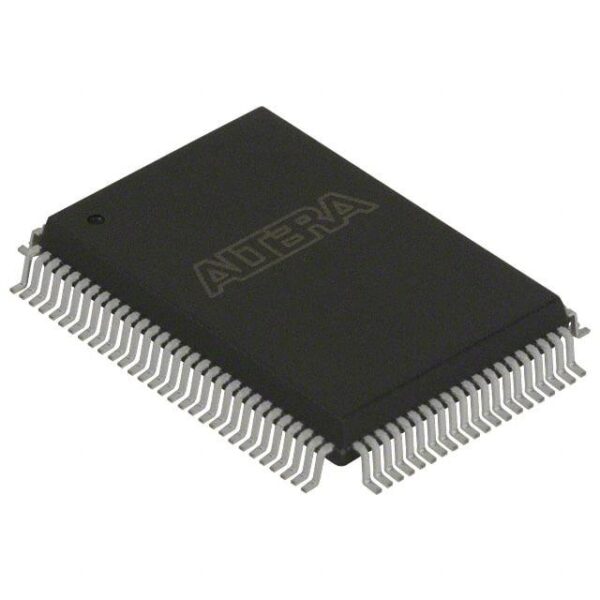

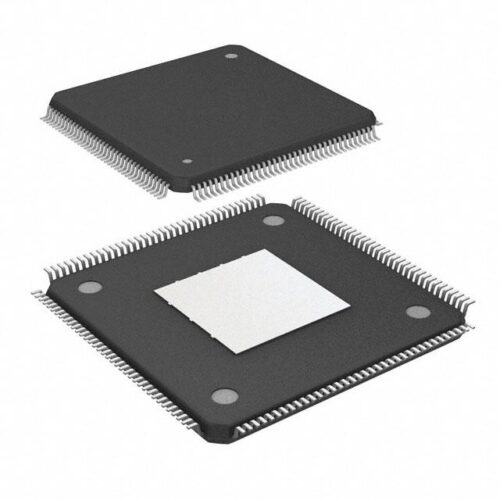

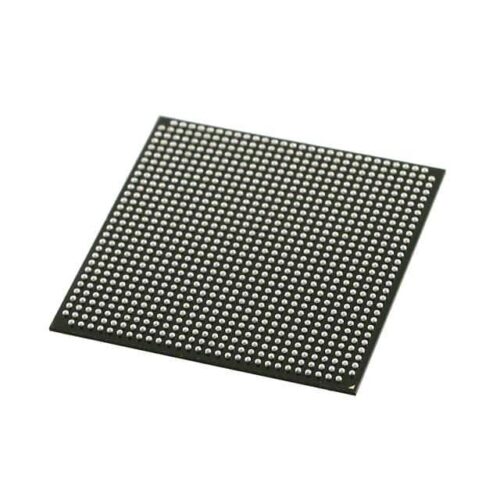

| Specification of EPM7128SQC100-7N | |

|---|---|

| Status | Obsolete |

| Series | MAX? 7000S |

| Package | Tray |

| Supplier | Intel |

| Digi-Key Programmable | Not Verified |

| Programmable Type | In System Programmable |

| Delay Time tpd(1) Max | 7.5 ns |

| Voltage Supply – Internal | 4.75V ~ 5.25V |

| Number of Logic Elements/Blocks | 8 |

| Number of Macrocells | 128 |

| Number of Gates | 2500 |

| Number of I/O | 84 |

| Operating Temperature | 0C ~ 70C (TA) |

| Mounting Type | Surface Mount |

| Package / Case | 100-BQFP |

| Supplier Device Package | 100-PQFP (20×14) |

Applications

The EPM7128SQC100-7N is ideal for high-performance computing environments, particularly in server racks where it can handle demanding computational tasks efficiently. It also excels in automotive applications, providing reliable performance under various conditions. Additionally, its robust design makes it suitable for industrial automation systems that require consistent operation across different environmental conditions.

Key Advantages

1. Operating Temperature Range: -40°C to +100°C

2. Advanced Cooling Technology

3. Energy Efficiency Rating: 90% at full load

4. CE, UL, and RoHS Certifications

Frequently Asked Questions

Q1: Can the EPM7128SQC100-7N operate effectively in extreme temperatures?

A1: Yes, it operates within a wide range from -40°C to +100°C, ensuring reliability in both cold and hot climates.

Q2: What certifications does the EPM7128SQC100-7N have?

A2: The EPM7128SQC100-7N has been certified to meet CE, UL, and RoHS standards, ensuring compliance with international safety and environmental regulations.

Q3: In which specific scenarios would the EPM7128SQC100-7N be most beneficial?

A3: This component is particularly beneficial in scenarios requiring high power density and high heat dissipation, such as in dense server farms and in harsh industrial environments.

Other people’s search terms

– High-Temperature Performance Components

– Automotive Grade Cooling Solutions

– Industrial Automation Cooling Systems

– Robust Server Cooling Units

– Energy-Efficient Cooling Technologies